Team members

Hidalgo Rodríguez Ana Karen

Rodríguez Matrínez José Alberto

Description

The spirometer is a measuring instrument used in medicine to determine lung volumes and capacities. Flow measurement was performed during ventilation from the readings of a differential pressure sensor. The Lilly configuration was used for spirometer design (Figure 1). The signal conditioning circuit was designed for proper acquisition using Arduino. Data transmission to the computer was done wirelessly. The digital processing of the obtained signal was done with a graphical interface in Matlab.

Figure 1. Lilly configuration pneumotach.

Obtained from: http://www.pftforum.com/blog/pneumotach-accuracy/

Physical Laws

Respiratory Flow

Air moves from a region of high pressure to another of lower pressure, gas exchange is possible by the difference of pressures. In the lungs, inspiration occurs when the alveolar pressure falls below atmospheric pressure as a negative pressure is generated due to the movement of the diaphragm and the walls of the chest, the expiration is carried out passively when the work required to overcome the friction resistance is lost.

In the turbulent flow the particles move heterogeneously across the flow, bumping against each other, causing fast and continuous flow mixing. The turbulence is described by the Reynolds number, that is calculated using equation (1).

Where:

ⲣ: density of the flux [kg / m3]

V: characteristic velocity of the fluid [m/s]

u: kinematic velocity of the fluid [kg/m*s]x10-5

D: diameter of the pipe through which the fluid flows [m]

v: dynamic flow velocity [m2/s]x10-5

If the Reynolds number is less than 2000 the flow will be laminar and if it is greater than 4000, the flow will be turbulent.

Objective

- Tobacco kills up to half of its consumers.

- Tobacco users who die prematurely deprive their families of income, increase the cost of health care and hinder economic development.

- Most smokers who know the dangers of tobacco want to quit. Counseling and medication can double the likelihood that a smoker who wants to quit will get it.

- There is no smoking cessation assistance in a quarter of low-income countries.

The objective of the project is to design a prototype spirometer that is capable of measuring the respiratory flow from a differential pressure and transmit the data obtained wirelessly to the computer for further processing, so smokers are aware of their progress and remain motivated to move forward.

Technical Data

Bandwidth: 0-10 Hz

Device amplification ratio: 63 000

CMRR:118

Components

- 1 MPX2200DP: silicon piezoresistive pressure sensor.

http://www.kosmodrom.com.ua/pdf/MPX2200.pdf

- 1 AD620: low cost, high accuracy instrumentation amplifier.

http://www.analog.com/media/en/technical-documentation/data-sheets/AD620.pdf

- 3 OPA2277: High-Precision, Low-Noise Operational Amplifier

http://www.ti.com/lit/ds/symlink/opa2277-ep.pdf

- Capacitors: 3x1uF, 820nF

- Resistors: 18Ω, 2x15KΩ, 2x2.2KΩ, 2x1KΩ, 22KΩ, 1.5KΩ, 3x330Ω, 2x4.7KΩ

- Arduino Leonardo: integrated USB HID Arduino board.

https://www.arduino.cc/en/Main/ArduinoBoardLeonardo -

- MATLAB: software to analyse and design systems and products; used in machine learning, signal processing, image processing, computer vision, communications, computational finance, control design, robotics, and more.https://www.mathworks.com/products/matlab.html

- Eagle PCB Design: software to bring designs to live by creating Printed Circuit Boards (PCB).https://cadsoft.io/

Instructions

Signal Acquisition:

Signal conditioning:

(2)

(2)

(3)

(3)

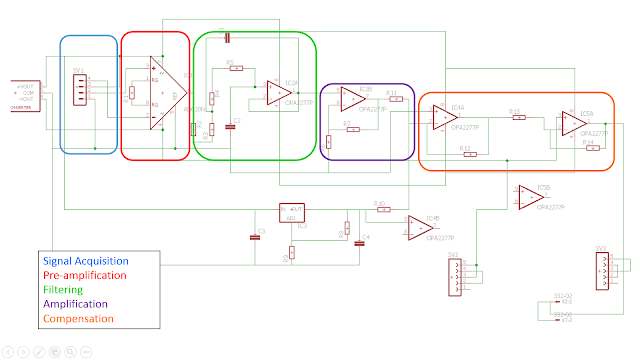

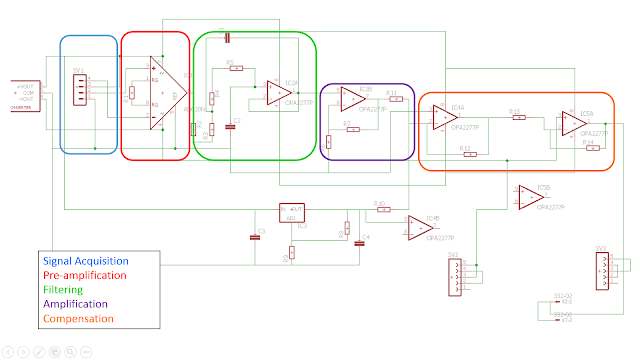

Figure 2. Acquisition and conditioning schematic circuit.

For the pressure measurements the silicon piezoresistive pressure sensor MPX220DP was used, which provides a precise and linear pressure output proportional to the applied pressure. The sensitivity of the sensor is 0.2 mV / kPa and with a dynamic differential pressure range of 0 to 200 kPa.

Signal conditioning:

Pre-amplification: an instrumentation amplifier AD620 was used to amplify the signal approximately 2,700 times, since the signal in the exit of the sensor is extremely small. The resistance for the amplifier was calculated using equation (2) shown below, the resulting resistance was 18 ohms.

Filtering: The filtering was performed with a low-pass filter of second order, with a cutoff frequency of 10Hz, of unity gain to filter the signal noise. The Sallen-Key configuration was chosen for its great performance. The values of capacitors and resistors were obtained from the transfer function shown in the equation (3).

Amplification: the amplification step was implemented in order to obtain a signal on a range of 5v between the minimum pressure and the maximum pressure mesured, a gain of 23 was calculated, a non-inverting amplifier was used and the resistances were calculated using the equation (4) shown below. Establishing R1 = 1Kohm, the calculated resistance was 22Kohms.

G=1+R2/R1 (4)

Compensation: finally an adder was done to eliminate the offset generated in the previous stages and to avoid damages for the Arduino. The inputs of the adder were the signal and 3v to carry the signal above 0v.

Figure 2 shows the acquisition and conditioning schematic circuit.

Figure 2. Acquisition and conditioning schematic circuit.

Figure 3. Acquisition and conditioning board circuit.

For the first stage, a function activates the serial communication with the port to which the Xbee receiver is connected to the computer and displays in real time a graph with the number of bits of the ADC corresponding to each sample on the vertical axis, and the time in milliseconds in which it was acquired on the horizontal axis.

In the second stage, by displaying a dialog box, two vectors are imported into the workspace ( "x" containing the number of amplitude bits of each sample and "t" which stores the time in milliseconds where each sample was acquired).

A second-order Butterworth low-pass filter with a cutoff frequency of 1 Hz was applied to the vector signal x to reduce the high frequency component noise generated by the Arduino.

Equation (5) was applied to each element of the vector "x" to convert it to voltage, since the Arduino assigns a value of 1024 bits for an input of 5V and from 0 to 0 V.

To convert the amplitude of the voltage signal to pressure, the known offset of the signal was removed and its amplitude divided by the total gain of the analog electronic circuit to estimate the voltage differential output of the pressure sensor, which was finally converted to pressure based on its sensitivity reported in its datasheet ie 0.2 mV per 1 kPa as shown in equation (6).

Where:

P: is each element of the pressure signal vector in Pascal (It represents the difference of pressures between both sides of the resistive membrane of the spirometer head).

Vin: is each element of the voltage signal vector obtained by equation 5.

Vof: is the offset voltage provided by the electronic circuit of the spirometer.

G: is the total gain of the electronic circuit of the spirometer.

%*******************Code for digital processing******************************

%To carry out digital processing, just have to implement this code in Matlab.

function varargout = interfaz_espirometro(varargin)

% INTERFAZ_ESPIROMETRO MATLAB code for interfaz_espirometro.fig

% INTERFAZ_ESPIROMETRO, by itself, creates a new INTERFAZ_ESPIROMETRO or raises the existing

% singleton*.

%

% H = INTERFAZ_ESPIROMETRO returns the handle to a new INTERFAZ_ESPIROMETRO or the handle to

% the existing singleton*.

%

% INTERFAZ_ESPIROMETRO('CALLBACK',hObject,eventData,handles,...) calls the local

% function named CALLBACK in INTERFAZ_ESPIROMETRO.M with the given input arguments.

%

% INTERFAZ_ESPIROMETRO('Property','Value',...) creates a new INTERFAZ_ESPIROMETRO or raises the

% existing singleton*. Starting from the left, property value pairs are

% applied to the GUI before interfaz_espirometro_OpeningFcn gets called. An

% unrecognized property name or invalid value makes property application

% stop. All inputs are passed to interfaz_espirometro_OpeningFcn via varargin.

%

% *See GUI Options on GUIDE's Tools menu. Choose "GUI allows only one

% instance to run (singleton)".

%

% See also: GUIDE, GUIDATA, GUIHANDLES

% Edit the above text to modify the response to help interfaz_espirometro

% Last Modified by GUIDE v2.5 05-Dec-2016 08:01:42

% Begin initialization code - DO NOT EDIT

gui_Singleton = 1;

gui_State = struct('gui_Name', mfilename, ...

'gui_Singleton', gui_Singleton, ...

'gui_OpeningFcn', @interfaz_espirometro_OpeningFcn, ...

'gui_OutputFcn', @interfaz_espirometro_OutputFcn, ...

'gui_LayoutFcn', [] , ...

'gui_Callback', []);

if nargin && ischar(varargin{1})

gui_State.gui_Callback = str2func(varargin{1});

end

if nargout

[varargout{1:nargout}] = gui_mainfcn(gui_State, varargin{:});

else

gui_mainfcn(gui_State, varargin{:});

end

% End initialization code - DO NOT EDIT

% --- Executes just before interfaz_espirometro is made visible.

function interfaz_espirometro_OpeningFcn(hObject, eventdata, handles, varargin)

% This function has no output args, see OutputFcn.

% hObject handle to figure

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

% varargin command line arguments to interfaz_espirometro (see VARARGIN)

% Choose default command line output for interfaz_espirometro

handles.output = hObject;

% Update handles structure

guidata(hObject, handles);

% UIWAIT makes interfaz_espirometro wait for user response (see UIRESUME)

% uiwait(handles.figure1);

% --- Outputs from this function are returned to the command line.

function varargout = interfaz_espirometro_OutputFcn(hObject, eventdata, handles)

% varargout cell array for returning output args (see VARARGOUT);

% hObject handle to figure

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

% Get default command line output from handles structure

varargout{1} = handles.output;

% --- Executes on button press in pushbutton1.

function pushbutton1_Callback(hObject, eventdata, handles)

% hObject handle to pushbutton1 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

AdquisicionDatos();

% --- Executes on button press in pushbutton2.

function pushbutton2_Callback(hObject, eventdata, handles)

% hObject handle to pushbutton2 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

[Archivo,Ruta]=uigetfile({'*.mat'},'Abrir archivo');

importfile(Archivo); %importar al workspace

t = evalin('base','t'); %importar desde el workspace

x = evalin('base','x');

t=t-t(1); %Iniciar en el tiempo 0s

%%Filtrar señal

%plot(t,x);

%title('Señal original')

%xlabel('Tiempo [s]');

%ylabel('Número de bits');

Fs=81;

orden=2;

freccorte=1;

d=fdesign.lowpass('N,F3dB',orden,freccorte,Fs);

Hbutter=design(d,'butter','SystemObject',true);

y=step(Hbutter,x);

%figure();

%plot(t,y);

%title('Señal filtrada');

%xlabel('Tiempo [s]');

%ylabel('Número de bits');

%Pasar señal a voltaje

y=y.*5/1024;

%figure();

%plot(t,y);

%title('Señal de voltaje');

%xlabel('Tiempo [s]');

%ylabel('Voltaje [V]');

%ubicar picos para encontrar un ciclo espiracion/inspiracion

%hold on

[p,l]=findpeaks(y);

%stem(t(l),p);

i=1;

while p(i)<4.0

i=i+1;

end %en i queda la localizacion en el vector de picos, del pico de la primer espiracion

j=l(i); %en j queda la localización en la señal, del pico de la primer espiracion

pico_espiracion=j;

while (y(j-1)<y(j))&&((y(j)-y(j-1))>0.001);

j=j-1;

end

inicio_espiracion=j; %indice donde está el inicio de la primer espiracion

offset=y(j);

%remover offset a la señal

y=y-offset;

%figure();

%plot(t,y);

%title('señal sin offset');

%encontrar final de la espiracion

i=pico_espiracion;

while y(i)>0

i=i+1;

end

fin_espiracion=i;

while y(i)<0

i=i+1;

end

fin_inspiracion=i;

%plotear un cilo espiracion/inspiracion

%figure()

%plot(t(inicio_espiracion:fin_inspiracion),y(inicio_espiracion:fin_inspiracion));

%title('Ciclo ventilatorio');

%axis tight

%Pasar a curva de presión

G=60390; %Ganancia del circuito analógico 2745x22

y=y./G;

presion=y.*(1000/0.0002);

%figure();

%plot(t(inicio_espiracion:fin_inspiracion),presion(inicio_espiracion:fin_inspiracion));

%title('Curva de presión');

%xlabel('Tiempo [s]');

%ylabel('Presión [Pa]');

%axis tight

%Recortar señal de tiempo y presion a solo lo de un ciclo inspiratorio

t_1=t(inicio_espiracion:fin_inspiracion);

t_1=t_1-t_1(1);

presion=presion(inicio_espiracion:fin_inspiracion);

%pasar a flujo

%Presion=flujo x resistencia

resistencia=0.06; %(Pa*s)/L

flujo=resistencia*presion;

%figure();

axes(handles.axes4);

plot(t_1,flujo);

%title('Curva de flujo');

xlabel('Tiempo [s]');

ylabel('Flujo [L/s]');

axis tight

grid on

%pasar a volumen

volumen=cumtrapz(t_1,flujo);

%figure();

axes(handles.axes7);

plot(t_1,volumen);

%title('Curva de volumen');

xlabel('Tiempo [s]');

ylabel('Volumen [L]');

axis tight

grid on

%Curva de presion volumen

%figure();

axes(handles.axes8);

plot(volumen,flujo);

%title('Curva de flujo-volumen');

xlabel('Volumen [L]');

ylabel('Flujo [L/s]');

axis tight

grid on

aux=t(fin_espiracion)-t(inicio_espiracion); %obtener tiempo de espiracion

set(handles.edit1,'String',aux); %desplegar tiempo de inspiracion

aux=t(fin_inspiracion)-t(fin_espiracion); %obtener tiempo de inspiracion

set(handles.edit2,'String',aux); %desplegar tiempo de inspiracion

% --- Executes on slider movement.

function slider2_Callback(hObject, eventdata, handles)

% hObject handle to slider2 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

% Hints: get(hObject,'Value') returns position of slider

% get(hObject,'Min') and get(hObject,'Max') to determine range of slider

% --- Executes during object creation, after setting all properties.

function slider2_CreateFcn(hObject, eventdata, handles)

% hObject handle to slider2 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles empty - handles not created until after all CreateFcns called

% Hint: slider controls usually have a light gray background.

if isequal(get(hObject,'BackgroundColor'), get(0,'defaultUicontrolBackgroundColor'))

set(hObject,'BackgroundColor',[.9 .9 .9]);

end

% --- Executes on slider movement.

function slider3_Callback(hObject, eventdata, handles)

% hObject handle to slider3 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

% Hints: get(hObject,'Value') returns position of slider

% get(hObject,'Min') and get(hObject,'Max') to determine range of slider

% --- Executes during object creation, after setting all properties.

function slider3_CreateFcn(hObject, eventdata, handles)

% hObject handle to slider3 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles empty - handles not created until after all CreateFcns called

% Hint: slider controls usually have a light gray background.

if isequal(get(hObject,'BackgroundColor'), get(0,'defaultUicontrolBackgroundColor'))

set(hObject,'BackgroundColor',[.9 .9 .9]);

end

% --- Executes on slider movement.

function slider1_Callback(hObject, eventdata, handles)

% hObject handle to slider1 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

% Hints: get(hObject,'Value') returns position of slider

% get(hObject,'Min') and get(hObject,'Max') to determine range of slider

% --- Executes during object creation, after setting all properties.

function slider1_CreateFcn(hObject, eventdata, handles)

% hObject handle to slider1 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles empty - handles not created until after all CreateFcns called

% Hint: slider controls usually have a light gray background.

if isequal(get(hObject,'BackgroundColor'), get(0,'defaultUicontrolBackgroundColor'))

set(hObject,'BackgroundColor',[.9 .9 .9]);

end

% --- Executes on button press in pushbutton3.

function pushbutton3_Callback(hObject, eventdata, handles)

% hObject handle to pushbutton3 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

% --- Executes on slider movement.

function slider5_Callback(hObject, eventdata, handles)

% hObject handle to slider5 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

% Hints: get(hObject,'Value') returns position of slider

% get(hObject,'Min') and get(hObject,'Max') to determine range of slider

% --- Executes during object creation, after setting all properties.

function slider5_CreateFcn(hObject, eventdata, handles)

% hObject handle to slider5 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles empty - handles not created until after all CreateFcns called

% Hint: slider controls usually have a light gray background.

if isequal(get(hObject,'BackgroundColor'), get(0,'defaultUicontrolBackgroundColor'))

set(hObject,'BackgroundColor',[.9 .9 .9]);

end

% --- Executes on button press in pushbutton5.

function pushbutton5_Callback(hObject, eventdata, handles)

% hObject handle to pushbutton5 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

% --- Executes on slider movement.

function slider4_Callback(hObject, eventdata, handles)

% hObject handle to slider4 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

% Hints: get(hObject,'Value') returns position of slider

% get(hObject,'Min') and get(hObject,'Max') to determine range of slider

% --- Executes during object creation, after setting all properties.

function slider4_CreateFcn(hObject, eventdata, handles)

% hObject handle to slider4 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles empty - handles not created until after all CreateFcns called

% Hint: slider controls usually have a light gray background.

if isequal(get(hObject,'BackgroundColor'), get(0,'defaultUicontrolBackgroundColor'))

set(hObject,'BackgroundColor',[.9 .9 .9]);

end

% --- Executes on button press in pushbutton4.

function pushbutton4_Callback(hObject, eventdata, handles)

% hObject handle to pushbutton4 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

function edit1_Callback(hObject, eventdata, handles)

% hObject handle to edit1 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

% Hints: get(hObject,'String') returns contents of edit1 as text

% str2double(get(hObject,'String')) returns contents of edit1 as a double

% --- Executes during object creation, after setting all properties.

function edit1_CreateFcn(hObject, eventdata, handles)

% hObject handle to edit1 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles empty - handles not created until after all CreateFcns called

% Hint: edit controls usually have a white background on Windows.

% See ISPC and COMPUTER.

if ispc && isequal(get(hObject,'BackgroundColor'), get(0,'defaultUicontrolBackgroundColor'))

set(hObject,'BackgroundColor','white');

end

function edit2_Callback(hObject, eventdata, handles)

% hObject handle to edit2 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

% Hints: get(hObject,'String') returns contents of edit2 as text

% str2double(get(hObject,'String')) returns contents of edit2 as a double

% --- Executes during object creation, after setting all properties.

function edit2_CreateFcn(hObject, eventdata, handles)

% hObject handle to edit2 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles empty - handles not created until after all CreateFcns called

% Hint: edit controls usually have a white background on Windows.

% See ISPC and COMPUTER.

if ispc && isequal(get(hObject,'BackgroundColor'), get(0,'defaultUicontrolBackgroundColor'))

set(hObject,'BackgroundColor','white');

end

%*****************Code has finished************************************

%Previously, you have to had alredy saved this function with the name: AdquisicionDatos

function AdquisicionDatos

close all; clear all; clc

fh = figure('Visible','off','Position',[200 200 1000 500]);

movegui(fh,'center')

ha = axes('Units', 'pixels', 'Position',[50, 50, 590, 400]);

sth1 = uicontrol(fh, 'Style', 'text',... % print time

'Position',[690 390 270 60], 'BackgroundColor', 'w',...

'FontSize', 30, 'ForegroundColor', [0 0 1]);

tbh1 = uicontrol(fh, 'Style', 'togglebutton',... % on/off

'Position', [690 330 80 40], 'FontSize', 14,...

'Callback', {@tbh1_Callback});

pbh1 = uicontrol(fh, 'Style', 'pushbutton',... % reset

'Position', [785 330 80 40], 'String', 'Reset',...

'FontSize', 14, 'Callback', {@pbh1_Callback});

pbh2 = uicontrol(fh, 'Style', 'pushbutton',... % reset

'Position', [880 330 80 40], 'String', 'Guardar',...

'FontSize', 13, 'Callback', {@pbh2_Callback});

sth2 = uicontrol(fh, 'Style', 'text',... % print time

'Position',[690 210 270 100], 'FontSize', 12,...

'HorizontalAlignment', 'Left');

set([fh, ha, sth1, tbh1, pbh1, pbh2, sth2], 'Units', 'normalized');

puerto = 'COM4';

delete(instrfind({'Port'},{puerto}))

s1 = serial(puerto, 'BaudRate', 9600);

[f, i, t_ant, t, x] = inicio(tbh1, sth1, sth2, pbh2);

[plotGraph, ymin, ymax, scrollWidth] = plot_inicio(ha, t, x);

set(fh,'Visible','on')

% *********************************************************************

% ********** Boton ON/OFF

function tbh1_Callback(hObject, eventdata)

tb_edo = get(hObject, 'Value');

%Boton estado ON

if tb_edo == get(hObject, 'Max')

f = 1;

set(tbh1, 'String', 'Off'); %Etiqueta On a Off

%Se abre el puerto y se inicia la comunicacion serial

set(sth2, 'String', sprintf('Estableciendo la comunicacion con el puerto: %s',puerto));

pause(1)

fopen(s1);

for j=1:1:100

data=fscanf(s1,'%f');

end

clear all

set(sth2, 'String', sprintf('Adquiriendo datos...'));

while f == 1 % ON (adquisición y despliegue)

i = i+1;

data = fscanf(s1,'%f');

t(i,1) = data(1);

x(i,1) = data(2);

if ((data(1)-t_ant) >= 100)

set(sth1, 'String', sprintf('%d [ms]', data(1)));

if(t(i)>scrollWidth)

set(plotGraph(1),'XData',t(t > t(i)-scrollWidth),...

'YData',x(t > t(i)-scrollWidth));

set(ha, 'XLim', [t(i)-scrollWidth t(i)], 'YLim', [ymin ymax]);

else

set(plotGraph(1),'XData', t,'YData',x);

set(ha, 'XLim', [0 scrollWidth], 'YLim', [ymin ymax]);

end

t_ant = data(1);

drawnow

end

end

end

%Boton estado OFF

if tb_edo == get(hObject,'Min')

set(sth2, 'String', sprintf('Cerrando la comunicacion con el puerto: %s',puerto));

pause(1)

%Se cierra el puerto serial

fclose(s1);

f = 0;

t = t/1000;

set(sth1, 'String', sprintf('%0.3f [s]', t(i)));

set(pbh2, 'Enable', 'On');

set(tbh1, 'Enable', 'Off');

reset(ha);

ymin = 0; ymax = 1023;

set(plotGraph(1),'XData',t,'YData',x);

set(ha, 'Box', 'on', 'XLim', [min(t) max(t)], 'YLim', [ymin ymax],...

'XGrid', 'on', 'YGrid', 'on');

set(get(ha,'XLabel'),'String','t [s]','FontSize',12,...

'FontWeight','bold')

Fs=length(x)/(max(t)-min(t));

set(sth2, 'String', sprintf('Frecuencia de muestreo:\t%.2f', Fs));

end

end

% % *************************************************************

function pbh1_Callback(hObject, eventdata) % RESET

set(sth2, 'String', sprintf('Espere mientras carga configuraciones iniciales'));

pause(1)

[f, i, t_ant, t, x] = inicio(tbh1, sth1, sth2, pbh2);

[plotGraph, ymin, ymax, scrollWidth] = plot_inicio(ha, t, x);

set(sth2, 'String', sprintf('Listo'));

end

function pbh2_Callback(hObject, eventdata) % GUARDAR

fileName = datestr(now, 'yymmddHHMMSS');

uisave({'t', 'x'}, fileName);

end

% % ***************************************************************

function [f, i, t_ant, t, x] = inicio(tbh, sth1, sth2, pbh2)

f = 0; i = 0;

t_ant = 0;

t = 0; x = 0;

set(pbh2, 'Enable', 'Off');

set(sth1, 'String', '0 [ms]');

set(sth2, 'String', {''});

set(tbh, 'String', 'On', 'Enable', 'on', 'Value', 0);

end

function [plotGraph, ymin, ymax, scrollWidth] = plot_inicio(ha, t,...

x)

ymin = 0; ymax = 1023; %Eje Y maximo y minimo

scrollWidth = 5000; % [ms] % 5000 milisegundos

plotGraph = plot(ha, t, x);

set(plotGraph(1),'LineWidth',2)

set(ha, 'Box', 'on', 'XLim', [0 scrollWidth], 'YLim', [ymin ymax],...

'XGrid', 'on', 'YGrid', 'on');

set(get(ha,'XLabel'),'String','t [ms]','FontSize',12,...

'FontWeight','bold')

end

end

%**********************Code has finished******************************

%*******************Code for digital processing******************************

%To carry out digital processing, just have to implement this code in Matlab.

function varargout = interfaz_espirometro(varargin)

% INTERFAZ_ESPIROMETRO MATLAB code for interfaz_espirometro.fig

% INTERFAZ_ESPIROMETRO, by itself, creates a new INTERFAZ_ESPIROMETRO or raises the existing

% singleton*.

%

% H = INTERFAZ_ESPIROMETRO returns the handle to a new INTERFAZ_ESPIROMETRO or the handle to

% the existing singleton*.

%

% INTERFAZ_ESPIROMETRO('CALLBACK',hObject,eventData,handles,...) calls the local

% function named CALLBACK in INTERFAZ_ESPIROMETRO.M with the given input arguments.

%

% INTERFAZ_ESPIROMETRO('Property','Value',...) creates a new INTERFAZ_ESPIROMETRO or raises the

% existing singleton*. Starting from the left, property value pairs are

% applied to the GUI before interfaz_espirometro_OpeningFcn gets called. An

% unrecognized property name or invalid value makes property application

% stop. All inputs are passed to interfaz_espirometro_OpeningFcn via varargin.

%

% *See GUI Options on GUIDE's Tools menu. Choose "GUI allows only one

% instance to run (singleton)".

%

% See also: GUIDE, GUIDATA, GUIHANDLES

% Edit the above text to modify the response to help interfaz_espirometro

% Last Modified by GUIDE v2.5 05-Dec-2016 08:01:42

% Begin initialization code - DO NOT EDIT

gui_Singleton = 1;

gui_State = struct('gui_Name', mfilename, ...

'gui_Singleton', gui_Singleton, ...

'gui_OpeningFcn', @interfaz_espirometro_OpeningFcn, ...

'gui_OutputFcn', @interfaz_espirometro_OutputFcn, ...

'gui_LayoutFcn', [] , ...

'gui_Callback', []);

if nargin && ischar(varargin{1})

gui_State.gui_Callback = str2func(varargin{1});

end

if nargout

[varargout{1:nargout}] = gui_mainfcn(gui_State, varargin{:});

else

gui_mainfcn(gui_State, varargin{:});

end

% End initialization code - DO NOT EDIT

% --- Executes just before interfaz_espirometro is made visible.

function interfaz_espirometro_OpeningFcn(hObject, eventdata, handles, varargin)

% This function has no output args, see OutputFcn.

% hObject handle to figure

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

% varargin command line arguments to interfaz_espirometro (see VARARGIN)

% Choose default command line output for interfaz_espirometro

handles.output = hObject;

% Update handles structure

guidata(hObject, handles);

% UIWAIT makes interfaz_espirometro wait for user response (see UIRESUME)

% uiwait(handles.figure1);

% --- Outputs from this function are returned to the command line.

function varargout = interfaz_espirometro_OutputFcn(hObject, eventdata, handles)

% varargout cell array for returning output args (see VARARGOUT);

% hObject handle to figure

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

% Get default command line output from handles structure

varargout{1} = handles.output;

% --- Executes on button press in pushbutton1.

function pushbutton1_Callback(hObject, eventdata, handles)

% hObject handle to pushbutton1 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

AdquisicionDatos();

% --- Executes on button press in pushbutton2.

function pushbutton2_Callback(hObject, eventdata, handles)

% hObject handle to pushbutton2 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

[Archivo,Ruta]=uigetfile({'*.mat'},'Abrir archivo');

importfile(Archivo); %importar al workspace

t = evalin('base','t'); %importar desde el workspace

x = evalin('base','x');

t=t-t(1); %Iniciar en el tiempo 0s

%%Filtrar señal

%plot(t,x);

%title('Señal original')

%xlabel('Tiempo [s]');

%ylabel('Número de bits');

Fs=81;

orden=2;

freccorte=1;

d=fdesign.lowpass('N,F3dB',orden,freccorte,Fs);

Hbutter=design(d,'butter','SystemObject',true);

y=step(Hbutter,x);

%figure();

%plot(t,y);

%title('Señal filtrada');

%xlabel('Tiempo [s]');

%ylabel('Número de bits');

%Pasar señal a voltaje

y=y.*5/1024;

%figure();

%plot(t,y);

%title('Señal de voltaje');

%xlabel('Tiempo [s]');

%ylabel('Voltaje [V]');

%ubicar picos para encontrar un ciclo espiracion/inspiracion

%hold on

[p,l]=findpeaks(y);

%stem(t(l),p);

i=1;

while p(i)<4.0

i=i+1;

end %en i queda la localizacion en el vector de picos, del pico de la primer espiracion

j=l(i); %en j queda la localización en la señal, del pico de la primer espiracion

pico_espiracion=j;

while (y(j-1)<y(j))&&((y(j)-y(j-1))>0.001);

j=j-1;

end

inicio_espiracion=j; %indice donde está el inicio de la primer espiracion

offset=y(j);

%remover offset a la señal

y=y-offset;

%figure();

%plot(t,y);

%title('señal sin offset');

%encontrar final de la espiracion

i=pico_espiracion;

while y(i)>0

i=i+1;

end

fin_espiracion=i;

while y(i)<0

i=i+1;

end

fin_inspiracion=i;

%plotear un cilo espiracion/inspiracion

%figure()

%plot(t(inicio_espiracion:fin_inspiracion),y(inicio_espiracion:fin_inspiracion));

%title('Ciclo ventilatorio');

%axis tight

%Pasar a curva de presión

G=60390; %Ganancia del circuito analógico 2745x22

y=y./G;

presion=y.*(1000/0.0002);

%figure();

%plot(t(inicio_espiracion:fin_inspiracion),presion(inicio_espiracion:fin_inspiracion));

%title('Curva de presión');

%xlabel('Tiempo [s]');

%ylabel('Presión [Pa]');

%axis tight

%Recortar señal de tiempo y presion a solo lo de un ciclo inspiratorio

t_1=t(inicio_espiracion:fin_inspiracion);

t_1=t_1-t_1(1);

presion=presion(inicio_espiracion:fin_inspiracion);

%pasar a flujo

%Presion=flujo x resistencia

resistencia=0.06; %(Pa*s)/L

flujo=resistencia*presion;

%figure();

axes(handles.axes4);

plot(t_1,flujo);

%title('Curva de flujo');

xlabel('Tiempo [s]');

ylabel('Flujo [L/s]');

axis tight

grid on

%pasar a volumen

volumen=cumtrapz(t_1,flujo);

%figure();

axes(handles.axes7);

plot(t_1,volumen);

%title('Curva de volumen');

xlabel('Tiempo [s]');

ylabel('Volumen [L]');

axis tight

grid on

%Curva de presion volumen

%figure();

axes(handles.axes8);

plot(volumen,flujo);

%title('Curva de flujo-volumen');

xlabel('Volumen [L]');

ylabel('Flujo [L/s]');

axis tight

grid on

aux=t(fin_espiracion)-t(inicio_espiracion); %obtener tiempo de espiracion

set(handles.edit1,'String',aux); %desplegar tiempo de inspiracion

aux=t(fin_inspiracion)-t(fin_espiracion); %obtener tiempo de inspiracion

set(handles.edit2,'String',aux); %desplegar tiempo de inspiracion

% --- Executes on slider movement.

function slider2_Callback(hObject, eventdata, handles)

% hObject handle to slider2 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

% Hints: get(hObject,'Value') returns position of slider

% get(hObject,'Min') and get(hObject,'Max') to determine range of slider

% --- Executes during object creation, after setting all properties.

function slider2_CreateFcn(hObject, eventdata, handles)

% hObject handle to slider2 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles empty - handles not created until after all CreateFcns called

% Hint: slider controls usually have a light gray background.

if isequal(get(hObject,'BackgroundColor'), get(0,'defaultUicontrolBackgroundColor'))

set(hObject,'BackgroundColor',[.9 .9 .9]);

end

% --- Executes on slider movement.

function slider3_Callback(hObject, eventdata, handles)

% hObject handle to slider3 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

% Hints: get(hObject,'Value') returns position of slider

% get(hObject,'Min') and get(hObject,'Max') to determine range of slider

% --- Executes during object creation, after setting all properties.

function slider3_CreateFcn(hObject, eventdata, handles)

% hObject handle to slider3 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles empty - handles not created until after all CreateFcns called

% Hint: slider controls usually have a light gray background.

if isequal(get(hObject,'BackgroundColor'), get(0,'defaultUicontrolBackgroundColor'))

set(hObject,'BackgroundColor',[.9 .9 .9]);

end

% --- Executes on slider movement.

function slider1_Callback(hObject, eventdata, handles)

% hObject handle to slider1 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

% Hints: get(hObject,'Value') returns position of slider

% get(hObject,'Min') and get(hObject,'Max') to determine range of slider

% --- Executes during object creation, after setting all properties.

function slider1_CreateFcn(hObject, eventdata, handles)

% hObject handle to slider1 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles empty - handles not created until after all CreateFcns called

% Hint: slider controls usually have a light gray background.

if isequal(get(hObject,'BackgroundColor'), get(0,'defaultUicontrolBackgroundColor'))

set(hObject,'BackgroundColor',[.9 .9 .9]);

end

% --- Executes on button press in pushbutton3.

function pushbutton3_Callback(hObject, eventdata, handles)

% hObject handle to pushbutton3 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

% --- Executes on slider movement.

function slider5_Callback(hObject, eventdata, handles)

% hObject handle to slider5 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

% Hints: get(hObject,'Value') returns position of slider

% get(hObject,'Min') and get(hObject,'Max') to determine range of slider

% --- Executes during object creation, after setting all properties.

function slider5_CreateFcn(hObject, eventdata, handles)

% hObject handle to slider5 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles empty - handles not created until after all CreateFcns called

% Hint: slider controls usually have a light gray background.

if isequal(get(hObject,'BackgroundColor'), get(0,'defaultUicontrolBackgroundColor'))

set(hObject,'BackgroundColor',[.9 .9 .9]);

end

% --- Executes on button press in pushbutton5.

function pushbutton5_Callback(hObject, eventdata, handles)

% hObject handle to pushbutton5 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

% --- Executes on slider movement.

function slider4_Callback(hObject, eventdata, handles)

% hObject handle to slider4 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

% Hints: get(hObject,'Value') returns position of slider

% get(hObject,'Min') and get(hObject,'Max') to determine range of slider

% --- Executes during object creation, after setting all properties.

function slider4_CreateFcn(hObject, eventdata, handles)

% hObject handle to slider4 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles empty - handles not created until after all CreateFcns called

% Hint: slider controls usually have a light gray background.

if isequal(get(hObject,'BackgroundColor'), get(0,'defaultUicontrolBackgroundColor'))

set(hObject,'BackgroundColor',[.9 .9 .9]);

end

% --- Executes on button press in pushbutton4.

function pushbutton4_Callback(hObject, eventdata, handles)

% hObject handle to pushbutton4 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

function edit1_Callback(hObject, eventdata, handles)

% hObject handle to edit1 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

% Hints: get(hObject,'String') returns contents of edit1 as text

% str2double(get(hObject,'String')) returns contents of edit1 as a double

% --- Executes during object creation, after setting all properties.

function edit1_CreateFcn(hObject, eventdata, handles)

% hObject handle to edit1 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles empty - handles not created until after all CreateFcns called

% Hint: edit controls usually have a white background on Windows.

% See ISPC and COMPUTER.

if ispc && isequal(get(hObject,'BackgroundColor'), get(0,'defaultUicontrolBackgroundColor'))

set(hObject,'BackgroundColor','white');

end

function edit2_Callback(hObject, eventdata, handles)

% hObject handle to edit2 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

% Hints: get(hObject,'String') returns contents of edit2 as text

% str2double(get(hObject,'String')) returns contents of edit2 as a double

% --- Executes during object creation, after setting all properties.

function edit2_CreateFcn(hObject, eventdata, handles)

% hObject handle to edit2 (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles empty - handles not created until after all CreateFcns called

% Hint: edit controls usually have a white background on Windows.

% See ISPC and COMPUTER.

if ispc && isequal(get(hObject,'BackgroundColor'), get(0,'defaultUicontrolBackgroundColor'))

set(hObject,'BackgroundColor','white');

end

%*****************Code has finished************************************

%Previously, you have to had alredy saved this function with the name: AdquisicionDatos

function AdquisicionDatos

close all; clear all; clc

fh = figure('Visible','off','Position',[200 200 1000 500]);

movegui(fh,'center')

ha = axes('Units', 'pixels', 'Position',[50, 50, 590, 400]);

sth1 = uicontrol(fh, 'Style', 'text',... % print time

'Position',[690 390 270 60], 'BackgroundColor', 'w',...

'FontSize', 30, 'ForegroundColor', [0 0 1]);

tbh1 = uicontrol(fh, 'Style', 'togglebutton',... % on/off

'Position', [690 330 80 40], 'FontSize', 14,...

'Callback', {@tbh1_Callback});

pbh1 = uicontrol(fh, 'Style', 'pushbutton',... % reset

'Position', [785 330 80 40], 'String', 'Reset',...

'FontSize', 14, 'Callback', {@pbh1_Callback});

pbh2 = uicontrol(fh, 'Style', 'pushbutton',... % reset

'Position', [880 330 80 40], 'String', 'Guardar',...

'FontSize', 13, 'Callback', {@pbh2_Callback});

sth2 = uicontrol(fh, 'Style', 'text',... % print time

'Position',[690 210 270 100], 'FontSize', 12,...

'HorizontalAlignment', 'Left');

set([fh, ha, sth1, tbh1, pbh1, pbh2, sth2], 'Units', 'normalized');

puerto = 'COM4';

delete(instrfind({'Port'},{puerto}))

s1 = serial(puerto, 'BaudRate', 9600);

[f, i, t_ant, t, x] = inicio(tbh1, sth1, sth2, pbh2);

[plotGraph, ymin, ymax, scrollWidth] = plot_inicio(ha, t, x);

set(fh,'Visible','on')

% *********************************************************************

% ********** Boton ON/OFF

function tbh1_Callback(hObject, eventdata)

tb_edo = get(hObject, 'Value');

%Boton estado ON

if tb_edo == get(hObject, 'Max')

f = 1;

set(tbh1, 'String', 'Off'); %Etiqueta On a Off

%Se abre el puerto y se inicia la comunicacion serial

set(sth2, 'String', sprintf('Estableciendo la comunicacion con el puerto: %s',puerto));

pause(1)

fopen(s1);

for j=1:1:100

data=fscanf(s1,'%f');

end

clear all

set(sth2, 'String', sprintf('Adquiriendo datos...'));

while f == 1 % ON (adquisición y despliegue)

i = i+1;

data = fscanf(s1,'%f');

t(i,1) = data(1);

x(i,1) = data(2);

if ((data(1)-t_ant) >= 100)

set(sth1, 'String', sprintf('%d [ms]', data(1)));

if(t(i)>scrollWidth)

set(plotGraph(1),'XData',t(t > t(i)-scrollWidth),...

'YData',x(t > t(i)-scrollWidth));

set(ha, 'XLim', [t(i)-scrollWidth t(i)], 'YLim', [ymin ymax]);

else

set(plotGraph(1),'XData', t,'YData',x);

set(ha, 'XLim', [0 scrollWidth], 'YLim', [ymin ymax]);

end

t_ant = data(1);

drawnow

end

end

end

%Boton estado OFF

if tb_edo == get(hObject,'Min')

set(sth2, 'String', sprintf('Cerrando la comunicacion con el puerto: %s',puerto));

pause(1)

%Se cierra el puerto serial

fclose(s1);

f = 0;

t = t/1000;

set(sth1, 'String', sprintf('%0.3f [s]', t(i)));

set(pbh2, 'Enable', 'On');

set(tbh1, 'Enable', 'Off');

reset(ha);

ymin = 0; ymax = 1023;

set(plotGraph(1),'XData',t,'YData',x);

set(ha, 'Box', 'on', 'XLim', [min(t) max(t)], 'YLim', [ymin ymax],...

'XGrid', 'on', 'YGrid', 'on');

set(get(ha,'XLabel'),'String','t [s]','FontSize',12,...

'FontWeight','bold')

Fs=length(x)/(max(t)-min(t));

set(sth2, 'String', sprintf('Frecuencia de muestreo:\t%.2f', Fs));

end

end

% % *************************************************************

function pbh1_Callback(hObject, eventdata) % RESET

set(sth2, 'String', sprintf('Espere mientras carga configuraciones iniciales'));

pause(1)

[f, i, t_ant, t, x] = inicio(tbh1, sth1, sth2, pbh2);

[plotGraph, ymin, ymax, scrollWidth] = plot_inicio(ha, t, x);

set(sth2, 'String', sprintf('Listo'));

end

function pbh2_Callback(hObject, eventdata) % GUARDAR

fileName = datestr(now, 'yymmddHHMMSS');

uisave({'t', 'x'}, fileName);

end

% % ***************************************************************

function [f, i, t_ant, t, x] = inicio(tbh, sth1, sth2, pbh2)

f = 0; i = 0;

t_ant = 0;

t = 0; x = 0;

set(pbh2, 'Enable', 'Off');

set(sth1, 'String', '0 [ms]');

set(sth2, 'String', {''});

set(tbh, 'String', 'On', 'Enable', 'on', 'Value', 0);

end

function [plotGraph, ymin, ymax, scrollWidth] = plot_inicio(ha, t,...

x)

ymin = 0; ymax = 1023; %Eje Y maximo y minimo

scrollWidth = 5000; % [ms] % 5000 milisegundos

plotGraph = plot(ha, t, x);

set(plotGraph(1),'LineWidth',2)

set(ha, 'Box', 'on', 'XLim', [0 scrollWidth], 'YLim', [ymin ymax],...

'XGrid', 'on', 'YGrid', 'on');

set(get(ha,'XLabel'),'String','t [ms]','FontSize',12,...

'FontWeight','bold')

end

end

%**********************Code has finished******************************

Results

In Figure 4 it is shown in pneumotacograph that was designed to obtain a laminar flow.

Figure 4. Pneumotacograph.

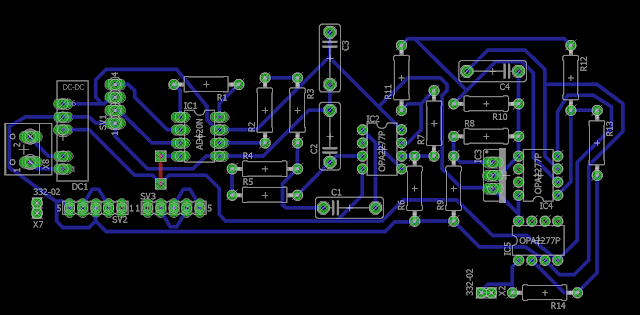

The PCB with the stages of amplification, filtering and compensation is shown in Figure 5.

Figure 5. Circuit in printed circuit board.

In Figure 6, the graphic interface with which the data transmitted from the spirometer to the computer was received is shown.

Figure 6. GUI for receiving wirelessly transmitted data.

Figure 7 shows the signal acquired in the previous step, given its amplitude in number of bits and time in seconds; it is affected by noise from high frequency components.

Figure 7. Original signal in number of bits and time in seconds.

In Figure 8 the previous signal is observed after the implementation of a Butterworth pass lows filter of second order and cutoff frequency of 1 Hz. The difference is remarkable, noting that the signal of physiological relevance is clearer.

Figure 8. Filtered signal.

The signal converted to its amplitude, from number of bits to voltage is observed in Figure 9. This is imperative to obtain the pressure difference at each point of the measurement. Also there can be observed detected peaks in signal which function to cut the signal in just one ventilatory cycle.

Figure 9. Spirometry signal with amplitude in voltage and time in seconds.

In Figure 10, the signal without acquisition offset is presented.

Figure 10. Spirometry signal without offset, with amplitude in pressure and time in seconds.

In Figure 11, graph shows one ventilatory cycle with amplitude in voltage and time in seconds.

Figure 11. Spirometry signal of one ventilatory cycle, with amplitude in pressure and time in seconds.

In Figure 12, graph shows one ventilatory cycle with amplitude in pressure and time in seconds.

Figure 12. Spirometry signal of one ventilatory cycle, with amplitude in pressure and time in seconds.

In Figure 13, there can be observed the curve of one ventilatory cycle with amplitude in flow and time in seconds.

Figure 13. Spirometry signal of one ventilatory cycle, with amplitude in flow and time in seconds.

In Figure 14, there can be observed the curve of one ventilatory cycle with amplitude in volume and time in seconds.

Figure 14. Spirometry signal of one ventilatory cycle, with amplitude in flow and time in seconds.

In Figure 15, there can be observed the curve of one ventilatory cycle with amplitude in flow against volume.

Figure 14. Spirometry signal of one ventilatory cycle, with amplitude in flow against flow.

Complete digital processing allows getting a similar result to the next, presented in Figure 15.

Figure 15. Graphic User Interface with result of processing one spirometry.

Conclusions

Biomedical instrumentation, as a branch of biomedical engineering, is constantly facing the challenge of developing and implementing techniques and technologies that fit the needs of clinical practice and improve its quality.From the measurement of a physical phenomenon it is possible to register others by indirect calculation.

It is important to take care that each stage works, the mechanical phase, the electronic phase and the processing phase.

No hay comentarios:

Publicar un comentario